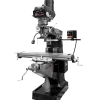

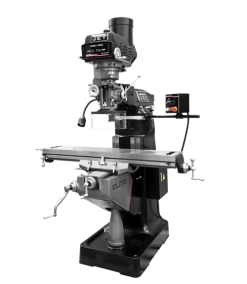

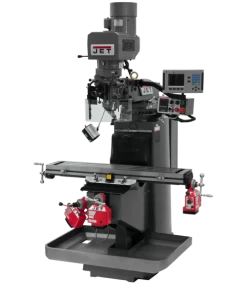

Jet 690948 JTM-4VS Mill With 3-Axis ACU-RITE G-2 MILLPWR CNC

$98.99

SKU: JB-DS-WLT-JT9-894100 Category: Power Tools

- Buy Quality, Live Better

- 100% High-Quality Guarantee

- Free Shipping Worldwide

- Protect Your Wallet with Safe Payments

Jet 690948 JTM-4VS Mill With 3-Axis ACU-RITE G-2 MILLPWR CNC

JET offers complete, factory-installed CNC packages with your choice of 2 or 3-axis CNC controls. The Computer Numerical Control system brings the added precision of digital automation to the process, allowing the user greater control and efficiency. Meehanite® casted JET Vertical Mills with CNC packages deliver accurate results every time. All the features you’ve come to expect backed by the industry-leading JET Two Year Warranty

- CNC Vertical Milling Machine Package JTM-4VS

- Features of the ACU-RITE MILLPWR G2 CNC Package

- Precision Ground Ball Screws eliminate backlash for precice lateral movements

- Closed loop feedback using Acu-Rite precision linear encoders with 0.00005″ resolution

- Powerful DC Servo motor assemblies that include mounting castings and hardware

- Handwheels are included for manual operation

- Features of the ACU-RITE MILLPWR G2 CONTROLLER

- USB + Ethernet compatible

- Simplified navigation that eliminates multiple menu screens

- 12.1″ High resolution display (1024 x 768) with 3D graphics

- 1 GHz Celeron® M processor

- Expanded tool library and Datum offsets

- Program preview provides a graphical representation prior to operation

- Progam size limit increased by 90% to 9,999 steps

- Jog Control allows table movement, quickly from one location to another – using one axis at a time or any two axes simultaneously

- 3-D Contouring, ability to import and run G-code files from CAD/CAM programs

- Mirror/Repeat/Rotate/Explode/Merge, easily manipulate, explode and merge part programs to save time and reduce program steps

- Menu-prompted Conversational programming, easily create part programs, edit, reverse, change, delete and copy/move steps – follow the menu prompts and let MILLPWR G2 do the rest

- Built-in Calculator, perform standard, trig and geometry calculations and transfer them directly into part programs

- Custom Pockets and Islands utilize the new optimized path and ramp feed features

- Circles including the Pocket, Frame, Ring and Helix incorporate the new ramp feed feature

- May be used automatically or manually for ultimate shop versatility

- Available offline software

- Estimated runtime feature

Specifications:

- Style (Type): CNC

- CNC Package: ACU-RITE MILLPWR® G2

- Number of Axis: 3

- Table Size (L x W) (In.): 9 x 49

- Spindle Taper (In. x TPI): R-8

- Quill Diameter (In.): 3-3/8

- Number of Spindle Speeds: Variable

- Range of Spindle Speeds (RPM): 60 – 4,200

- Quill Down Feed Rates (IPR): .0015 – .003 – .006

- Spindle Travel (In.): 5

- Head Movement (Deg.): 90° R & L, 45° F & B

- Max Distance Spindle to Table (In.): 17-1/2

- Distance Spindle to Column (Max.) (In.): 19

- Distance Spindle to Column (Min.) (In.): 4-1/2

- Collet Capacity: 1/8 – 7/8

- Table Longitudinal Travel (In.): 34

- Table Cross Travel (In.): 12

- T-Slots Number and Size (In.): 3 and 5/8

- T-Slot Centers (In.): 2-1/2

- Work Table Weight Capacity (Lbs.): 660

- Travel of Knee (In.): 14-1/2

- Travel of Ram (In.): 13-3/8

- Motor (HP): 3 HP, 230/460V, 3Ph

- Overall Dimensions (L x W x H) (In.): 66 x 63 x 85

- Weight (Lbs.): 2,420

Be the first to review “Jet 690948 JTM-4VS Mill With 3-Axis ACU-RITE G-2 MILLPWR CNC” Cancel reply

Related products

$22.18

$8.40

$98.99

$98.99

Reviews

There are no reviews yet.